Heat Disinfect RO & Distribution Loop (MediQA/Heatsan)

AmeriWater’s MediQA Heat Disinfect Reverse Osmosis can be combined with the Heatsan Loop Heat Disinfection System. When coupled with pre-treatment, this fully integrated water purification solution provides a complete heat disinfect system for 6 to 40 stations (Heat Disinfect RO and Heat Disinfect Distribution Loop).

Reverse Osmosis

AmeriWater’s MediQA Heat Disinfect Reverse Osmosis System use proven reverse osmosis technology to provides a superior blend of reliability, efficiency and patient safety. Systems with single or dual pass membranes are available. With automated heat disinfection of RO membranes, MediQA units ensure that any potential for bacterial growth on membrane surfaces is minimized. User-friendly operation is managed through a full color touch screen display with comprehensive menu navigation – including full schematics. Password protected stored data includes active status indicators, alarm conditions and performance logs. The stored data can be downloaded to a remote PC or accessed through the touch screen.

Loop Heat Disinfect

The Heatsan from AmeriWater is an integrated heat disinfection system for the distribution loop with a significant advantage: the ability to adjust operation for each day of the week, heating intervals, holding times and disinfection temperatures. As a result, the Heatsan can save energy and staff time while providing up to 100 gallons of 185°F water for disinfection. Incorporating a PLC controller, the Heatsan is operated by a dual color touch screen displaying alarms, system status, tank level and disinfection temperatures plus a password-protected event log holding up to 12 months of data. The construction is rugged yet space-efficient featuring a stainless steel skid and an insulated stainless steel storage tank with sloping base fitted with three heating elements to minimize electrical consumption, level transmitter and temperature monitor.

Features

Reverse Osmosis Features:

- High recovery mode uses up to 40% less water during operation and results in 100% recirculation.

- Emergency single pass mode (ESPM) allows the MDP systems to automatically transition to single pass operation in the event of a pump failure.

- High flow model available for facilities with larger flow requirements.

- Single and dual pass membrane configurations provides maximum flexibility in water quality.

- Automated heat disinfection of RO membranes ensures that any potential for bacterial growth on membrane surfaces is minimized

- Full color touch screen display with comprehensive menu navigation, including full schematics.

- Advanced data logging technology with password protection.

- Information available via an integrated touch screen display or downloaded to Excel.

- Stored data includes active status indicators, alarm conditions and performance logs.

- 8” TFC membranes in FRP vessels for durability.

- Powder coated aluminum skid mounted package on castors for maximum maneuverability.

Loop Heat Disinfect Features:

- Easy step through programming (7 day program)

- Program syncs dialysis machines with the Heatsan

- Intelligent monitoring routines, leak detection, and over use

- Heat disinfect will abort if leak is detected

- Four levels of password protection

- Event log holds up to 12 months of data including AAMI standards required end of loop history

- USB download to Excel

- Stainless steel skid complete with insulated stainless steel storage tank with sloping base fitted with three heating elements to minimize electrical consumption, level transmitter and temperature monitor

- Stainless steel recirculation pump, stainless steel solenoid valves

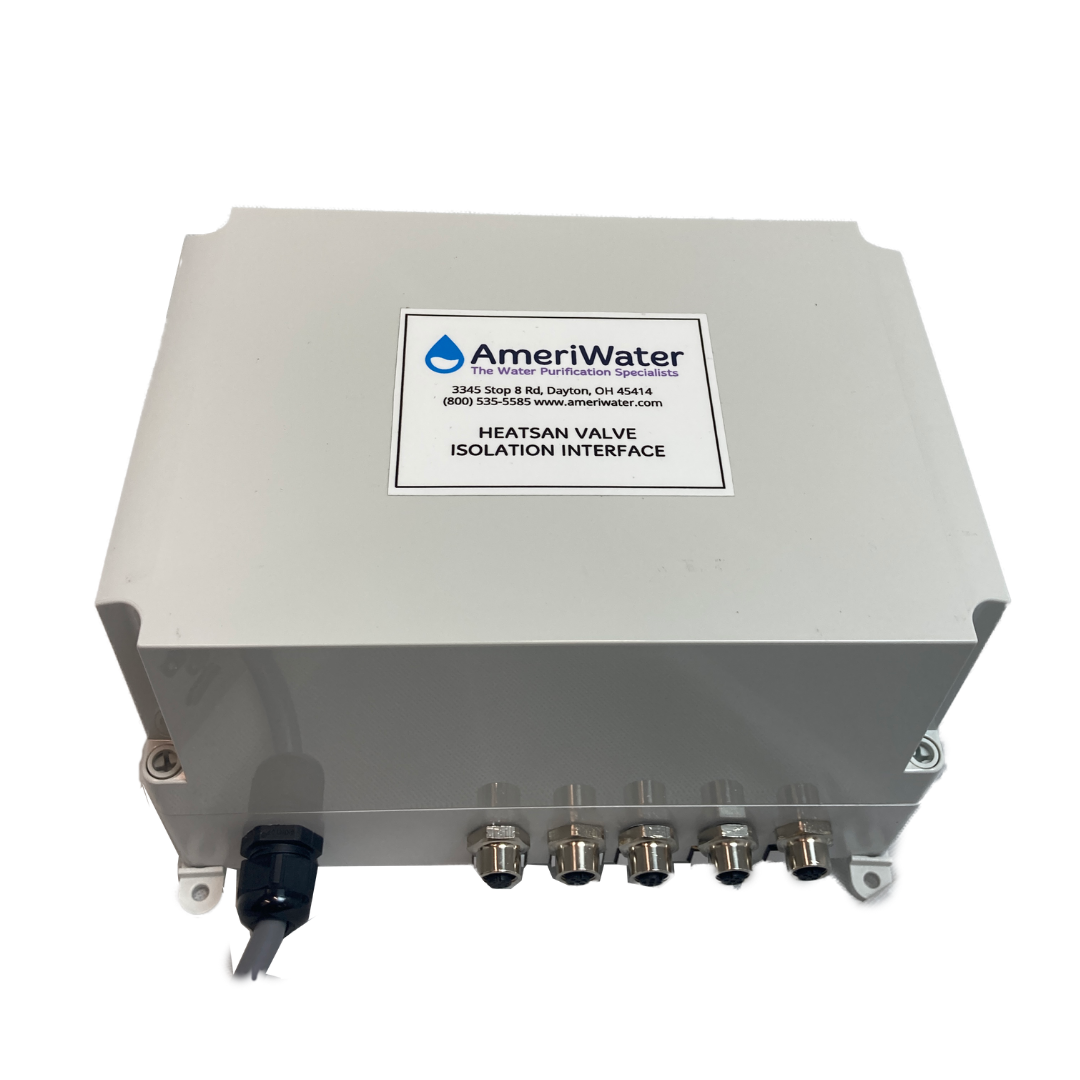

- The isolation of the RO system is accomplished with three way motorized ball valves that are controlled by the Heatsan

Specifications

| Reverse Osmosis Specifications: | ||||||

| Membranes | TFC Heat Disinfectable | Water Conversion | 50 – 75% | |||

| Salts Rejection | > 94% | Feed Water | ||||

| pH Tolerance | 6 - 8 | Total Dissolved Solids | < 1000 ppm | |||

| Connections | Chlorine | < 0.1 ppm | ||||

| Feed Water | 1.25” FNPT | Hardness | < 4 ppm at CaCO3 | |||

| Overflow Tank Drain | 1.5” FNPT | Fouling Index (SDI) | < 5 | |||

| Concentrate (reject) | 1” FNPT | Pressure (PSI) | 30 - 80 | |||

| Permeate (product) | 1” FNPT | Temperature | 55 - 90°F | |||

| Loop Return | 1” FNPT | |||||

| Single Pass | Dual Pass | |||||

| Models | 00MSP2-230 | 00MSP3-230 | 00MSP3HF-230 | 00MDP2-230 | 00MDP4-230 | |

| Gallons/Day* (up to) | 12,960 | 17,280 | 23,040 | 7,920 | 14,400 | |

| Gallons/Minute* (up to) | 9 | 12 | 16 | 5.5 | 10 | |

| Number of Membranes | 2 | 3 | 3 | 3 | 5 | |

| Replacement Membrane | R22-8041 (8” x 40”) | |||||

| Minimum Feed Flow (GPM) | 26 | 29 | 30 | 29 | 30 | |

| Power | 208/230V, 60 Hz, 3 phase with dedicated neutral and ground | |||||

| Max. Current Draw (Amps) | 44 | 44 | 44 | 44 | 59 | |

| Shipping Weight Lbs. | 1,050 | 1,100 | 1,120 | 1,370 | 1,970 | |

| Operation Weight Lbs. | 1,310 | 1,375 | 1,395 | 1,660 | 2,285 | |

| Dimensions In. (W x D x H) | 40 x 63 x 74 | 40 x 75 x 74 | ||||

| * Permeate flow rate at 77°F. Variations in feed water temperature can affect output by up to ±3% per degree Fahrenheit. Based on 1,000 microsiemens water or less. This sheet is not to be used for sizing purposes. Contact an AmeriWater representative and provide a loop design to properly size the system. | ||||||

| Loop Heat Disinfect Specifications: | ||||||

| Model | HS20809 | HS20815 | ||||

| Electrical | 208-230V, 40 Amp Service ,3 Ph, 9kw Heater Power | 208-230V, 60 Amp Service (47 Amps draw), 3 Ph, 15kw Heater Power | ||||

| Performance | Tank Volume | 100 Gallons (380 Liters) | ||||

| Pump Output Range | 5.2 GPM @ 80 PSI 19.3 GPM @ 30 PSI |

|||||

| Designed Max. Water Temperature | 203°F | |||||

Certifications

- Entire device conforms to IEC UL standard 61010-1

- FDA 510K / ISO 13485 Registered Medical Device