Sterile Processing Water Systems – Up to 4,200 GPD

Water Treatment Solutions to help you meet the AAMI ST108 Standard

For Applications Requiring Up To 4,200 GPD

Ensuring optimal water quality is essential to safeguard patient well-being and prolong the lifespan of medical equipment. Water used for sterile processing is under the guidance of ANSI/AAMI ST108:2023, Water for the Processing of Medical Devices. This standard places significant importance on ensuring proper water system design, monitoring, testing, and maintenance. AmeriWater’s Water Filtration Package combined with proper maintenance and monitoring will help you to meet the ST108 requirements.

By implementing AmeriWater’s comprehensive system, healthcare facilities can enjoy the benefits of critical water that meets the specific requirements of washers, disinfectors, glassware washers, steam boilers, and final rinses. AmeriWater’s advanced water filtration system ensures cleaner instruments without mineral deposits, extends the lifespan of equipment, reduces, or eliminates boiler scale, and enhances cleaning quality and efficiency.

Features

- Carbon pre-filter for chlorine removal

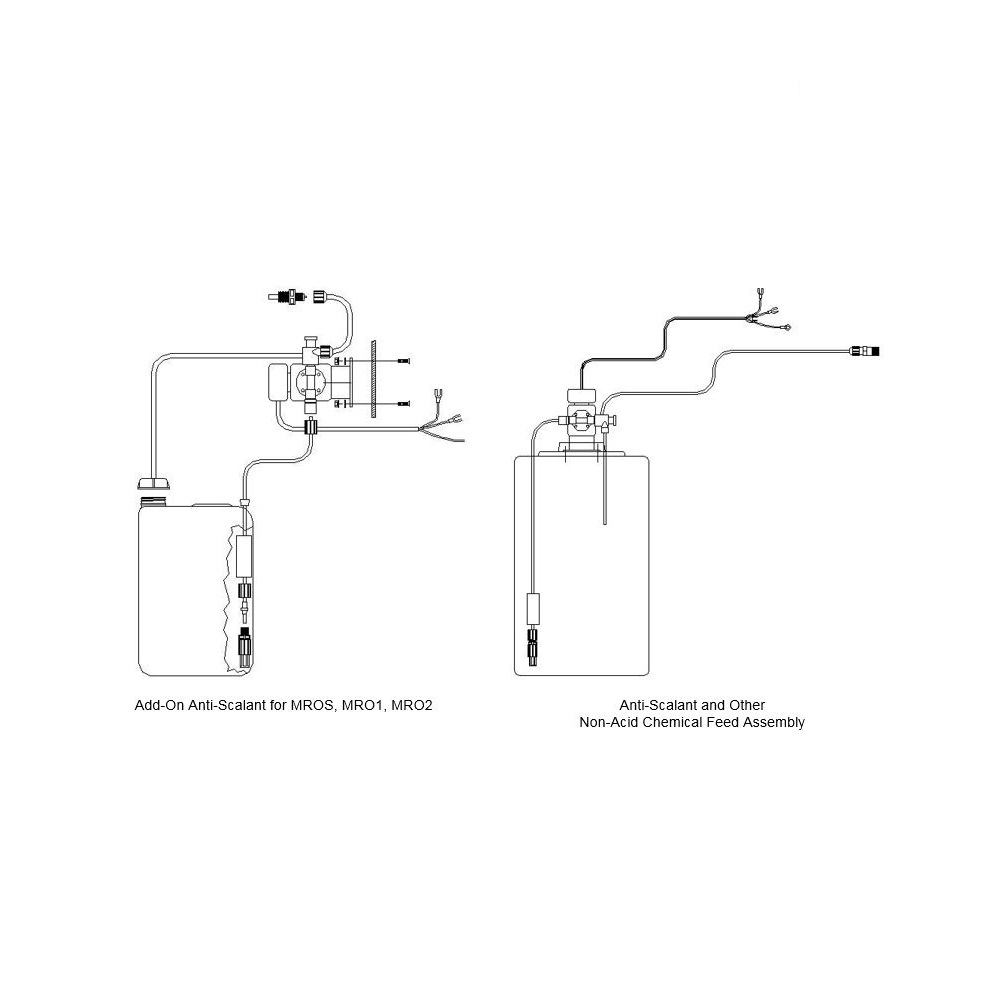

- Anti-scalant injection feed to prevent hard water scale on reverse osmosis membranes

- RO system with:

– Low feed pressure system shut down / alarm

– High conductivity of feed and product water - Polish DI with either Silex Deionizer or DI exchange tanks handled by local DI exchange provider

- Storage tank with sealed lid

– Distribution pump sized to meet system requirements with shut down on empty storage tank

– Submicron vent filter

– Distribution loop return manifold

– Pressure relief valve

– Distribution loop return flow meter

– Sample port

– Distribution loop to drain valve

– Internal spray nozzle - Ultraviolet Light

– Controls bacteria proliferation in purified water storage and distribution systems

– Equipped with an online monitor to measure output intensity and alarms when lamp needs replaced - Ultrafiltration

– 0.2 Submicron Endotoxin Cartridge

– Installed post UV to remove endotoxins from the purified water storage and distribution system - Alarm Panel

– Monitors system operating conditions

– Includes RO alarm, low storage tank, and DI resistivity

– Remote alarm included for continuous system monitoring outside water room - System can be easily disinfected

Specifications

- Drain: One 1½” Floor Drain or Sink

- Feed Water Quality: Potable Drinking Water Standards

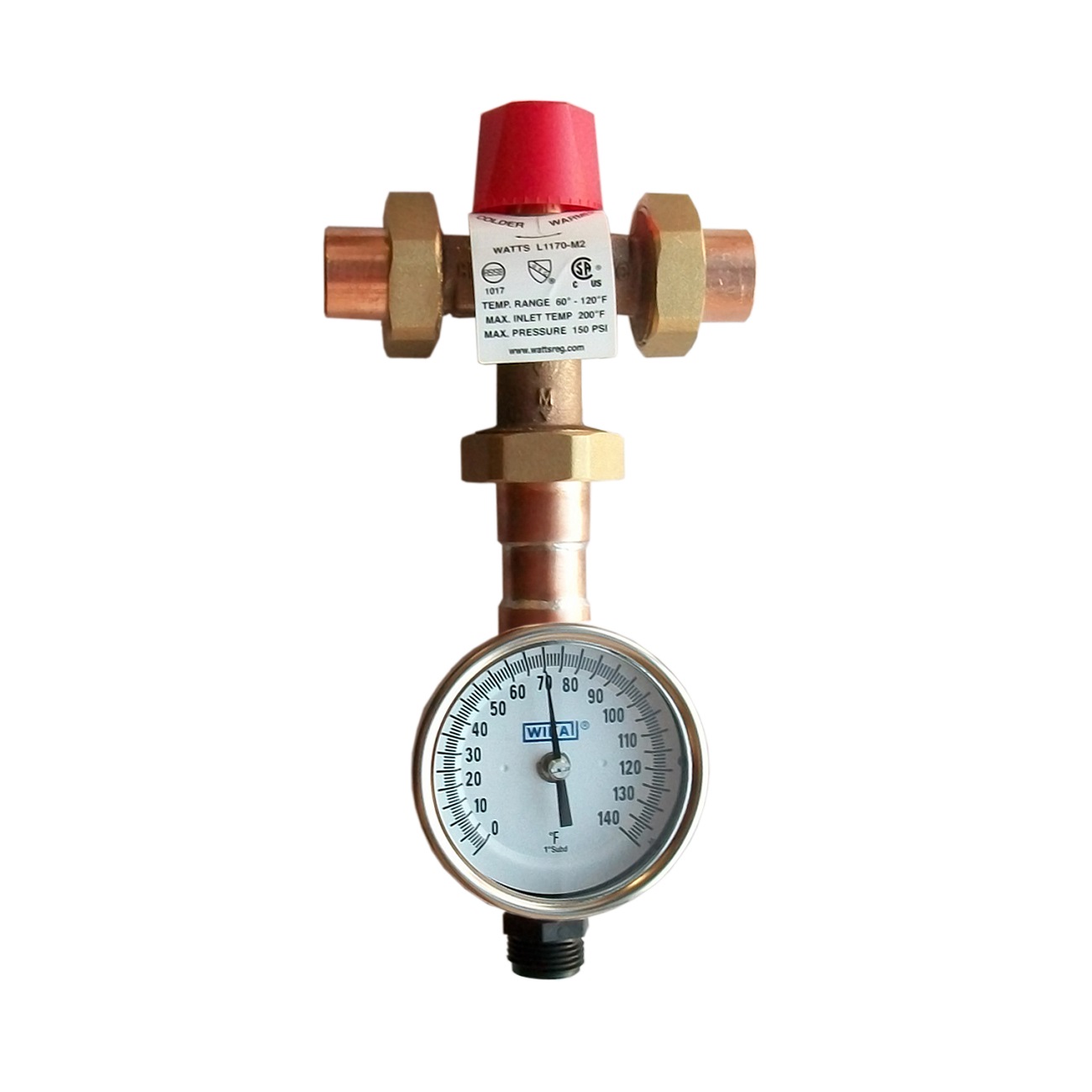

- Feed Water Temperature: 77°F (Blend Valve Recommended)

- Feed Water Flow Minimum: Between 41°F – 90°F

- Feed Water Pressure Min./Max.: 20/50 PSI

- Projected Rejection: > 96%

- Distribution Pump Output: 30 GPM at 30 PSI

- RO Production Rated Capacity*: 4,200 GPD / 15,897 LPD

| Deionizer | Pump Output | Tank Size (GALS) | Model | Dimensions |

| Option | High Flow | 100 | 00HC-3022 | 90x36x78 |

| Option | High Flow | 185 | 00HC-3024 | 92x36x108 |

| * Product flow rate varies with temperature and inlet pressure. All models are rated at 77°F with feed water of 1500 mg/l NaCl @ 55 PSI feed pressure and pH of 7.5. As a safety factor use 60% of the rated capacity when sizing or add blend valve to temper the feed water. | ||||

Certifications

- ETL Listed, Conforms to UL Std 61010-1

- Certified CAN/CSA C22.2 No. 61010-1

- ISO 13485 Registered Device

- Seismic OPA-2202-07

Accessories

Downloads

Download >

Download >